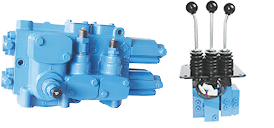

As a professional custom hydraulic valve solution provider with over 10 years of experience and knowledgeable technical team, Gaoyu specializes in designing and manufacturing hydraulic valves with various functions, including directional valves, speed control valves, brake valves, etc. In addition, we also offer custom service to satisfy your special expectations.

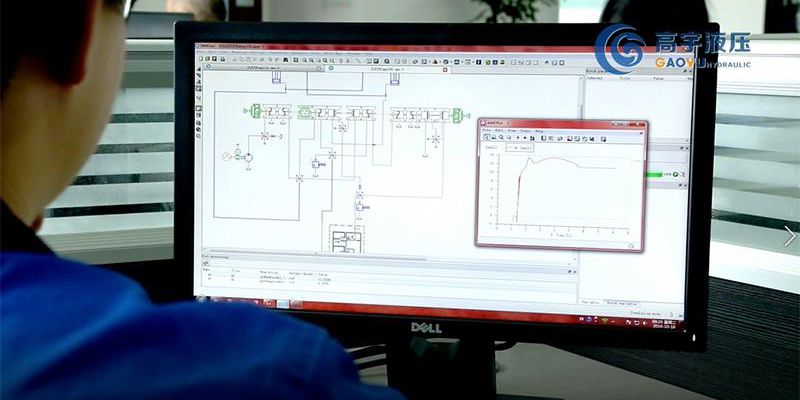

Digital production guarantees product quality and reduces costs. We are committed to improve our manufacturing capability with advanced software technology, including Pro/Engineer, AMEsim, PTC.MathCAD, SolidWorks, PCCAD V12, Product Data Management (PDM), data exchange platform and other test equipment like LERC for data collection and failure analysis.

From the implementation of our digital production platform to the development of software and hardware, Gaoyu Hydraulic always focuses on product quality. We set up a research and development centre that is well equipped with test equipment. With our strong experience and expertise, we have successfully received more than 20 national patents.

Our machine shop covers an area of over 6,000 m² with more than 50 processing equipment, including 20 CNC machines: CNC honing machine, horizontal machining center, and fully automated robotic machining center. Every hydraulic valve is manufactured using these high precision devices to guarantee the quality of the product.

The valves are cleaned with pressure and a high flow rate. It is then assembled and tested with constant temperatures by our experienced workers. Their efficient teamwork improves efficiency and ensures the reliability of our products.

Horizontal Machining Center

Horizontal Machining Center Fully Automated Robotic Machining Center

Fully Automated Robotic Machining Center

360° cleaning with no dead corner is achieved using 30 Mpa high pressure flushing and multi-axis coordination. Different flushing guns are optional according to different valve’s body, meeting different cleaning requirement. The high pressure flushing equipment is designed with PNC (programmable numerical control) system to reach high efficiency and to ensure consistent cleanliness level.

With high automation, the assembly line is well built according to product assembly sequence to ensure quick operation in each station, maximizing working efficiency and productivity.

Quality control is the key to the reliability of the product. Our product quality is thoroughly and strictly controlled by advanced test equipment and highly qualified quality inspectors.

Our specialists are ready to assist with any inquiries you have, providing comprehensive pre-sale guidance and dedicated after-sales support.